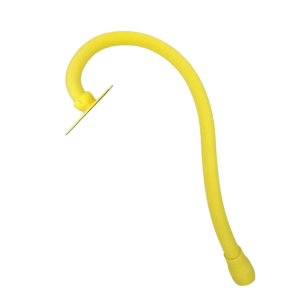

Gas Cap Turner

Illinois Assistive Technology Program (IATP)’s Demonstration Center has a similar, manufactured gas cap opener for individuals to test, but unfortunately the measurements required modifications to fit Teresa’s vehicle’s gas cap handle. With the collaboration of Teresa, her sister, and the Makers team, they were able to get the correct measurements of the handle and the space around it to make the necessary changes to the gas cap opener. The handle was also slightly extended to provide easier access for Teresa and built up for a more secure grip. The device was quickly printed and shipped to Teresa to begin using it as soon as possible.

The Makers program can not only design and fabricate assistive technology devices that do not exist but can also investigate modeling and modifying already existing designs to fit the customized needs of the individual requesting it.

Hand Grip Writing Device

IATP’s Makers Program quickly designed and 3D-printed one small enough for the student and to fit a marker inside. A threaded heat set insert was installed into the device to allow for a screw to be used to hold the marker in place or any other writing utensil, big or small, while the device is in use.

Medical Patch Applicator

This device was designed for a client in need of a device to help her mother with her ability to apply her medication patch. Her mother suffers from chronic shoulder pain, which limits her range of motion. They tried every kind of product that was commercially available, but nothing could help her apply her patch in the correct location. They heard about the IATP Maker program and were curious to see if we could provide a solution. After two prototypes, the Makers found a solution that would work. The lidocaine patch lightly sticks to the applicator and the handle design allows her to position the patch where needed and transfer it to her body using very little pressure.

Apple Keyboard Stand

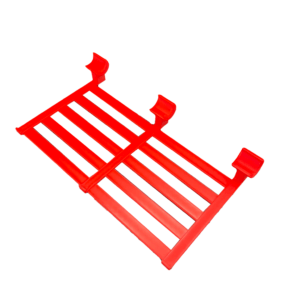

Sandwich Bag Assist

IATP’s Tech Kitchen program met with a customer who had only use of one hand and was interested in learning how assistive technology devices could help him be more independent in the kitchen. A request was submitted to the IATP Makers Program for a device to hold Ziplock and toaster bags open while he puts his food inside. The Makers Program then presented various designs using open source files and some designed in-house.

A similar device exists on the market, and is currently in the Tech Kitchen’s demonstration inventory, although it did not work for the customer’s specific needs. Ultimately, the Tech Kitchen decided on an open source design which was then modified to hold the bags in place more appropriately for a one-handed user, therefore making it functional for the customer. The device also contains an adhesive tape attached to the bottom for additional stabilization on countertops.

Headrest Switch Mount

An IATP Speech-Language Pathologist submitted a referral to Makers on behalf of an IATP customer she had provided with an Augmentative and Alternative Communication (AAC) evaluation. The customer requires the use of a head-activated switch to navigate her device. Our SLP noticed that the swing-away switch mounts on both sides of the wheelchair headrest were bulky and appeared unsafe for the client’s younger children, causing a high risk of pinching fingers. The swing-away mounts also cause wear and tear on the headrest cover.

The Makers team fabricated two symmetrical mounts that clip onto the side of the headrest, including Velcro attachments to hold the switches when activated via lateral sides of the individual’s head. Both mounts were printed in under two hours. This simplified solution is safer and more convenient than wheelchair mounts she previously used.